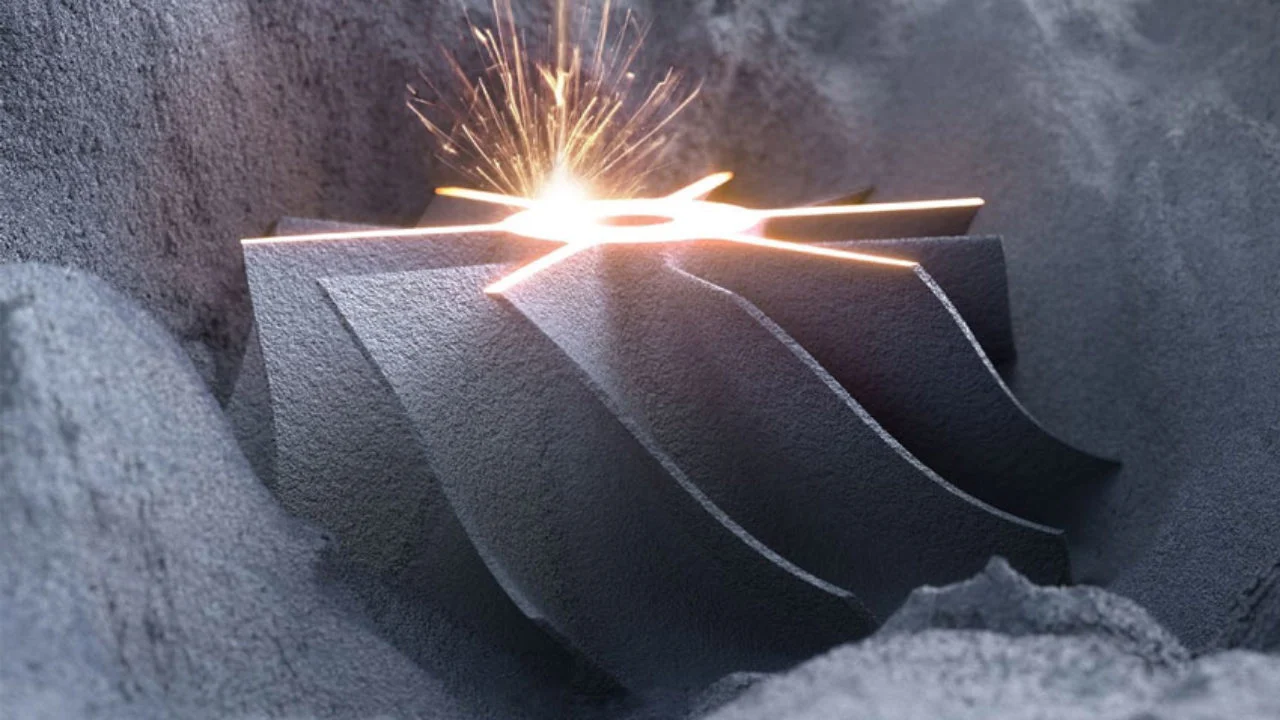

Laser Powder Bed Fusion (LPBF): What You Need to Know About Metal 3D Printing

Image Source: The Steel Printers

When people think of 3D printing, they often imagine plastic prototypes or hobbyist parts. But in advanced industries, the real game-changer is metal additive manufacturing. At the heart of this transformation lies Laser Powder Bed Fusion (LPBF), a cutting-edge process that is reshaping how critical components are designed and produced.

What You’ll Learn:

What Exactly Is Laser Powder Bed Fusion (LPBF)?

Laser Powder Bed Fusion (LPBF) is a metal 3D printing technology that uses a high-powered laser to selectively melt fine layers of metal powder. The process happens inside a controlled, inert environment to prevent oxidation. Layer after layer, the powder is spread, fused, and solidified until a fully dense, high-strength metal part emerges.

Think of it like building a skyscraper: each floor must be laid precisely before the next can begin. In LPBF, each “floor” is a thin layer of powder, melted and bonded into place by the laser until the part grows to its final shape.

Unlike conventional manufacturing that cuts material away from a solid block, LPBF builds parts from the ground up with minimum waste. This makes it not just innovative, but also resource-efficient.

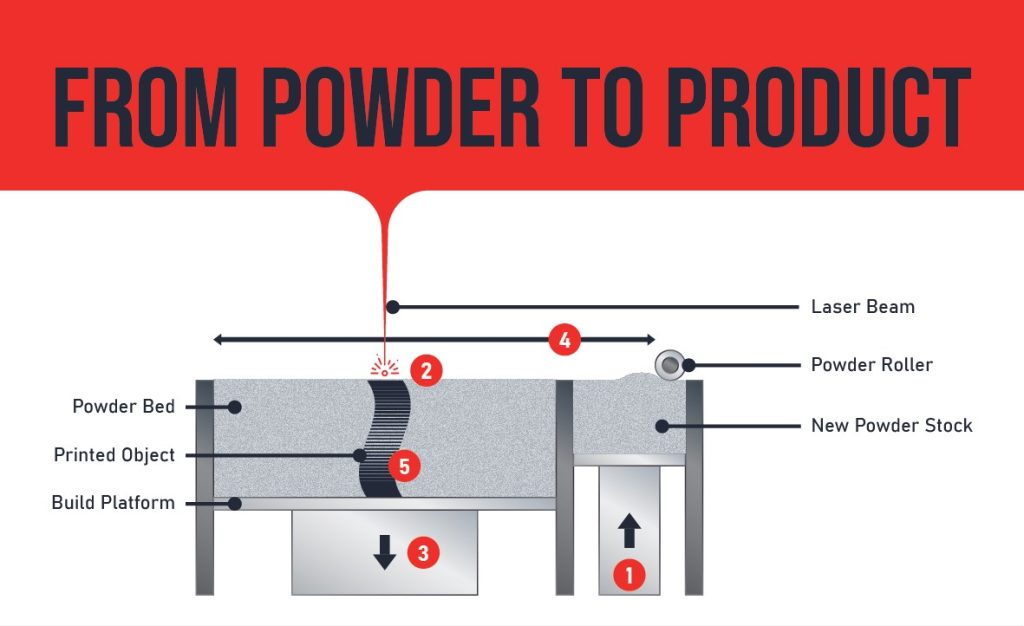

Image Source: 3Dnatives

Why LPBF Matters in Metal Additive Manufacturing?

LPBF isn’t just another manufacturing method. It unlocks possibilities that traditional techniques simply cannot achieve:

Unmatched Design Freedom

Internal cooling channels, lattice structures, and organic geometries that cannot be machined are now within reach. This means engineers can prioritize function over manufacturability, pushing the limits of innovation.

Near-Net Shape Accuracy

LPBF can achieve tolerances as tight as ±0.2 mm, reducing or even eliminating the need for heavy post-machining. This not only saves production time but also ensures parts meet demanding specifications right off the build plate.

Lightweight Yet Strong

By removing unnecessary material without sacrificing integrity, LPBF enables optimized parts that are both lighter and stronger. In industries like aerospace and motorsport, this translates directly into improved efficiency and performance.

Material Efficiency

Unlike subtractive methods that waste large amounts of raw material, LPBF reuses unused powder. Excess powder can be collected, sieved, and recycled for future builds, helping manufacturers reduce costs while meeting sustainability goals.

Consolidation of Parts

Complex assemblies that once required multiple components, fasteners, and joints can now be printed as a single, integrated unit. This reduces weak points, streamlines production, and simplifies inventory management.

How the LPBF Process Works?

- Powder Spreading: A thin layer of metal powder is evenly distributed across the build platform.

- Laser Melting: A laser precisely melts the powder in areas defined by the digital design, fusing it into a solid cross-section.

- Layering: The platform lowers slightly, and a new layer of powder is spread over the previous one.

- Repetition: The laser melts the next layer, bonding it to the one below. This cycle repeats until the full part is complete.

- Final Part: After printing, the part is removed, cleaned of excess powder, and post-processed (such as heat treatment or machining if required).

What Metals Can Be Printed with LPBF?

LPBF is designed exclusively for metals, making it distinct from other 3D printing processes that use polymers. Commonly used materials include:

Titanium alloys

Cobalt-chrome

Copper

Platinum

Bronze

Gold

Nickel-based alloys

Tantalum

Aluminum alloys

Stainless steel

*While technically possible, precious metals like gold, platinum, or tantalum are rarely printed with LPBF due to cost, reflectivity, and high risk of system damage.

Challenges and Limitations of LPBF

While Laser Powder Bed Fusion (LPBF) is transforming metal manufacturing, it’s not without its hurdles. Understanding these challenges is key to making the most of the technology.

Build Size Limitations

LPBF printers are confined by the size of their build chambers. Large components often need to be printed in sections and then joined, which can add cost and complexity. This makes LPBF ideal for small to medium-sized, high-value parts rather than oversized structures. Engineers must carefully plan designs around these dimensional constraints.

Residual Stresses and Warping

The intense heating and cooling cycle of the laser can cause thermal stresses inside the part. Without proper design orientation and post-processing, this may lead to distortion or cracking. Advanced simulation tools and heat treatment are often used to minimize these risks, but they add another layer of expertise and cost to the process.

Post-Processing Requirements

Freshly printed parts usually need additional finishing such as machining, heat treatment, or Hot Isostatic Pressing (HIP) to meet surface quality and performance standards. These steps are especially critical in aerospace and medical industries, where safety and precision cannot be compromised. In many cases, post-processing represents a significant portion of the overall production time and cost.

High Cost of Materials and Equipment

High-quality metal powders are expensive, and LPBF machines require significant investment. For mass production of low-cost parts, traditional manufacturing can still be more economical. However, the cost is often justified for applications where performance, weight reduction, or design freedom deliver long-term value.

Quality Assurance and Certification

Industries like aerospace and healthcare demand strict compliance and repeatability. Every part must be tested to prove it meets the required mechanical properties, density, and safety standards. Ensuring consistent powder quality, validating processes, and passing certification audits can be challenging but they are essential for scaling LPBF into production.

Where LPBF Is Making the Biggest Impact?

From lightweight satellite brackets to intricate turbine blades, LPBF allows engineers to design lighter, stronger, and more reliable parts. By reducing component count and optimizing designs, aircraft and spacecraft can achieve better fuel efficiency and durability.

What makes this impact so significant is the ability to combine multiple functions into a single printed part, eliminating joints, fasteners, and weak points. This not only cuts weight but also improves long-term reliability in demanding environments. Beyond aerospace, sectors like healthcare, automotive, and energy are embracing LPBF to produce patient-specific implants, lightweight vehicle components, and high-performance heat exchangers that traditional methods simply cannot achieve.

Image Source: ebeammachine

The Future of Manufacturing Is Layer by Layer

Image Source: Prima Additive

Laser Powder Bed Fusion (LPBF) has moved beyond being a niche technology. It is now a cornerstone of modern metal additive manufacturing, helping companies move faster from design to production while embracing sustainability and efficiency. For industries where precision, strength, and design freedom are critical, LPBF has proven itself as a reliable and effective solution.

What makes LPBF especially valuable is its ability to bridge the gap between innovation and real-world application, allowing companies to move from concept to certified parts without the delays of traditional methods. As organizations continue to seek ways to reduce waste, streamline workflows, and enhance product performance, LPBF stands out as a practical path forward.

Whether you’re experimenting with prototypes, scaling up to production, or exploring lightweight designs for critical applications, our team brings the expertise and technology to make it happen.