Beyond Prototypes: The Role of 3D Printing in Next-Generation Vehicles

What You’ll Learn in This Guide

Introduction: Why Cars and 3D Printing Are a Perfect Match

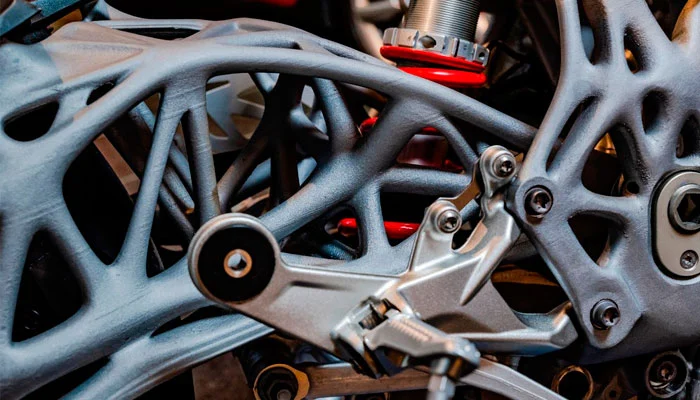

In today’s race to innovate, the automotive industry is shifting gears and 3D printing is helping it accelerate. From electric vehicles to autonomous driving, automakers are under pressure to deliver smarter, lighter, and safer cars faster than ever. Traditional manufacturing struggles to keep up with these demands.

3D printing, once limited to prototypes, is now creating production-ready parts that meet real-world performance and regulatory standards. With lightweight, durable, and thermally stable materials, the technology is rewriting the rules of automotive engineering.

Image Source: Press BMW Group

From Prototypes to Production: Why Automakers Are Betting on 3D Printing

Image Source: 3D Natives

Freedom to design without geometric constraints. Freedom to iterate faster. Freedom to reduce part counts. And most importantly, freedom to reduce weight without sacrificing strength. Key reasons why the industry is adopting it:

- Design Flexibility – Engineers can create complex geometries that are impossible or too costly with traditional methods.

- Rapid Prototyping – Parts can be iterated and tested within days instead of weeks.

- Cost Efficiency – Particularly for low-volume or custom parts, 3D printing removes tooling costs and reduces waste.

- Lightweighting – Advanced materials enable strong yet lightweight components, contributing to improved fuel economy and extended EV range.

Performance Under Pressure: What Automotive Parts Really Need

Cars don’t live in a lab. Parts must survive heat, vibration, fluids, and real-world abuse. Here’s how 3D printing is stepping up:

High-Temperature Resistance

Under-the-hood components face extreme heat near engines and exhaust systems. High temperature materials like PEKK, ULTEM™, and PAEK, known for their thermal stability, are used to print housings, ducts, and brackets that can handle continuous temperatures above 150°C.

Chemical Resistance

From brake fluid to engine oil to road salt, automotive parts must resist chemical degradation. Materials such as nylon, polypropylene, and carbon-fiber reinforced polymers are ideal for components exposed to harsh fluids, including fuel-line connectors, pump housings, and underbody covers.

Lightweight and Structural Strength

Every gram counts, especially in EVs. 3D printing allows complex lightweight structures such as lattice infills, using titanium, aluminum, or high-performance polymers. This balance of strength and weight is essential for suspension parts, mounts, and structural supports.

Vibration Damping and Noise Control

Comfort is a priority, particularly in electric vehicles where engine noise is reduced. Flexible materials like TPU (thermoplastic polyurethane) help absorb vibration and lower noise levels. Applications include bushings, seals, gaskets, and custom-fit interior trims.

Impact Resistance

Safety-critical parts must withstand shocks, crashes, or rough terrain. 3D-printed components made from polycarbonate, ABS, or reinforced composites provide toughness for bumper elements, protective housings, and interior panels.

Roadblocks to Adoption: Challenges Automakers Face

Of course, it’s not all smooth driving. Automakers face real barriers before scaling up 3D printing:

Material

Limitations

Not every material is printable, and not every printable material has the mechanical properties required for demanding automotive applications. Some aerospace-grade metals with extremely high melting points are still beyond the reach of most AM systems.

Post-Processing Requirements

Printing does not end when the part comes off the machine. Processes such as surface finishing, heat treatment, machining, and coating are often required, which add time, cost, and complexity.

Certification and Validation

Unlike casting or injection molding with decades of proven data, 3D-printed parts must undergo rigorous testing to meet regulations. Validation for fatigue resistance, crash performance, and long-term durability is complex and time-consuming.

How the Industry is Overcoming These Barriers

The good news is that the industry is actively addressing these challenges through key advancements:

Material Innovation

Scientists are developing new material blends such as carbon fiber reinforced PEEK, ESD-safe nylons, and flexible thermoplastics with higher tear strength. These unlock new applications and allow direct substitution for metals or molded parts.

Process Optimization

3D printing workflows are being improved for better consistency and surface quality. AI-driven simulation, in-situ monitoring, and closed-loop feedback systems are making industrial printers more reliable and scalable.

Industry Collaboration

Automakers, 3D printing OEMs, and certification bodies are working together to define standards, testing protocols, and traceability systems. This collaboration is laying the groundwork for safe, repeatable mass production.

Choosing the Right 3D Printing Materials for Automotive Success

Selecting materials isn’t just about printability. It’s about strategy. Engineers typically consider these 5 factors:

Mechanical Properties

Parts must be strong, tough, and wear-resistant. Structural components may require high tensile strength, while moving parts might need low-friction materials.

Thermal Stability

Heat resistance is crucial for parts near engines or exhaust systems. PEEK and ULTEM™ are common choices.

Chemical Resistance

Exposure to fuels, oils, UV, and road chemicals can weaken some materials. Composites and high-performance plastics such as nylon or polypropylene are preferred in these environments.

Regulatory Compliance

Materials must meet global safety and quality standards such as ISO or AIAG requirements.

Cost-Effectiveness

Performance must be balanced with budget. Factors include material cost, print speed, and waste reduction.

Bugatti’s 3D-Printed Titanium Brake Caliper

Bugatti, in collaboration with Laser Zentrum Nord in Hamburg, has developed the world’s first 3D-printed titanium brake caliper, representing the largest functional titanium component produced by additive manufacturing to date.

Traditionally manufactured from aluminum alloys, brake calipers face limitations in both strength and weight optimization. By leveraging selective laser melting (SLM) and aerospace-grade Ti6Al4V alloy, Bugatti achieved what was previously considered unattainable. Key outcomes include:

- 40% weight reduction compared to aluminum calipers.

- High strength, with titanium sustaining loads of more than 125 kg per mm².

- Optimized geometry, combining stiffness with reduced mass — only achievable through additive manufacturing.

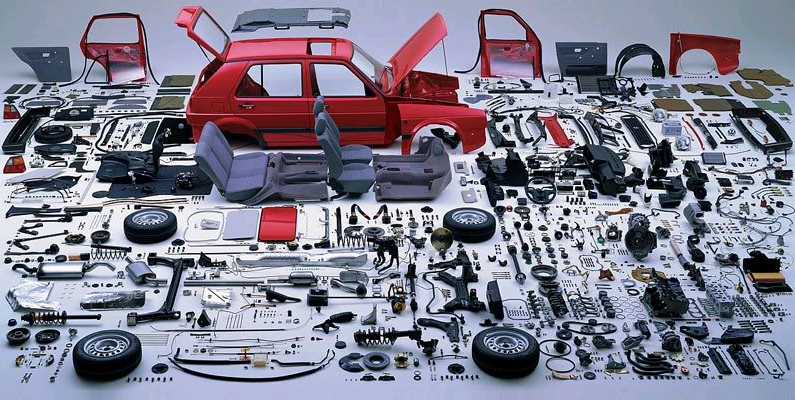

The Road Ahead: Where 3D Printing Will Take Us Next

Image Source: 3D Print

As the technology matures, the role of 3D printing in automotive manufacturing will only expand. Expect to see hybrid vehicles with printed housings, EVs with thermally managed battery enclosures, and interiors featuring customized, comfort-focused designs.

It is not about replacing traditional manufacturing. It is about reimagining what is possible.

3D printing gives automotive engineers a powerful toolkit to create smarter, stronger, and more efficient vehicles. And in a market where innovation drives success, that is a competitive edge worth investing in.

Want to understand the metal side of this transformation? Read our LPBF article next.

Ready to explore 3D printing for your automotive projects?